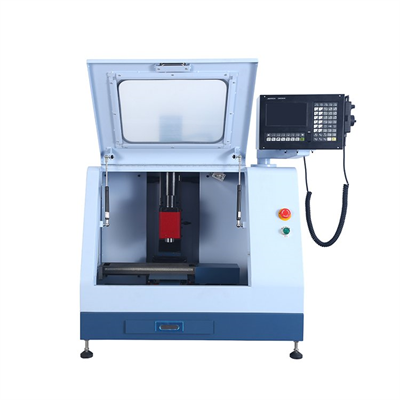

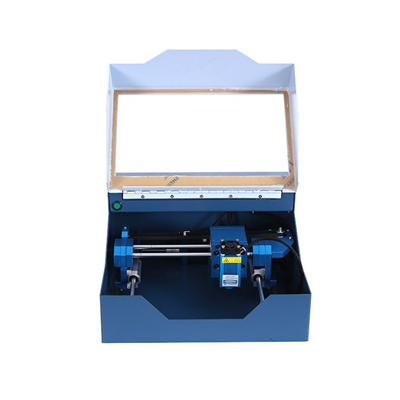

High efficiency numerical control metal sawing machine

Point control

only controls the accurate positioning of the tool from one point to another, and does not control the movement track (such as numerical control drilling machine, punch machine). Suitable for positioning needs such as hole machining.

Linear control

Control the accurate positioning and movement track between points and points as a straight line, while controlling the movement speed (such as simple numerical control lathe). Suitable for rectangular, step-shaped parts processing.

Contour control

Continuous control of the displacement and speed of two or more motion coordinates to realize complex curved surface processing (such as numerical control milling machine, machining center). Interpolation operation function is required to ensure that the tool moves along the contour of the workpiece.

Economical numerical control machine

simple function, suitable for small batch, single variety processing, low cost.

Full-function numerical control machine

has complete numerical control function, supports multi-coordinate linkage, complex surface processing (such as five-axis machining center).

High-grade numerical control machine

integrates advanced technologies such as high-speed machining, intelligent monitoring, and adaptive control to meet high-end manufacturing needs such as aerospace.