Advantages of mechanical spindle of large numerical control engraving and milling machine

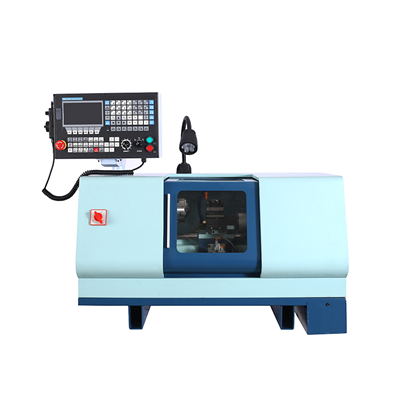

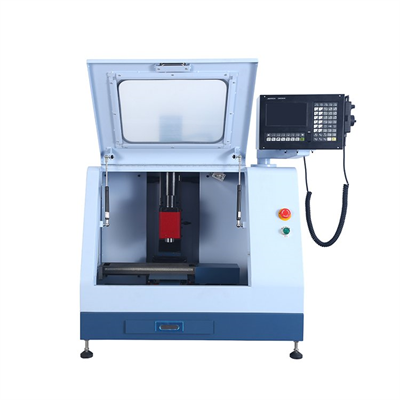

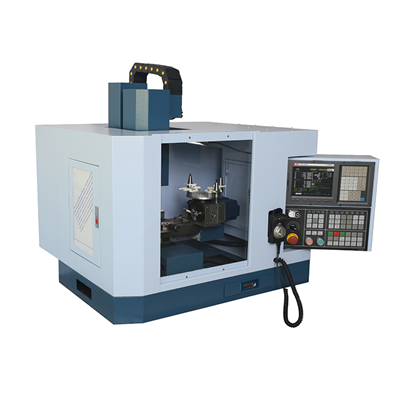

Large numerical control engraving and milling machine is a new type of numerical control machine tool gradually developed in recent years. It makes up for the single defect of traditional numerical control machine tools and overcomes the shortage of high processing cost of light and small products. It has played a very important role in people's production and processing, shoe making, sculpture, etc. The difference between

engraving and milling machine and traditional machine tools lies in the configuration of the mechanical spindle. It has unique advantages over others.

First of all, in terms of efficiency, its mechanical spindle can continuously fine-tune the speed, and can perfectly control the cutting speed throughout the machining process, so as to obtain extremely high processing efficiency.

Secondly, in the generated noise, its noise value can reach g1, and the spindle rotates at high speed, its noise is very small. The general engraving and milling machine in the process of use, the noise is relatively large, causing fixed failure to the operator.

Third, the engraving and milling machine adopts high-precision imported parts of imported bearings, and precision assembly and testing can easily meet the higher requirements of processing and production. In addition, in terms of running speed, the mechanical spindle of the large numerical control engraving and milling machine adopts high-speed precision matching with imported bearings, rigid or elastic preload structure, which can obtain higher speed, so that the tool can play a better cutting effect. With the formulation and implementation of the new five-year plan, the large numerical control milling machine will be more and more widely recognized and applied in the future development of our country's manufacturing industry.

Development and prospect of numerical control engraving and

Development and prospect of numerical control engraving and

Advantages of mechanical spindle of large numerical control

Advantages of mechanical spindle of large numerical control

The numerical control engraving and milling machine with str

The numerical control engraving and milling machine with str

Machining center numerical control engraving and milling mac

Machining center numerical control engraving and milling mac