Machining center numerical control engraving and milling machine price fluctuation factor

The price of numerical control engraving machine machinery and equipment has always been a concern of enterprises. Vertical machining centers can complete milling, boring, drilling, tapping, tangential and other processes. In fact, whether it is an imported machining center, a Taiwan machining center or a domestic machining center, the machining center itself, even if the same brand, the same model of vertical machining centers, different prices are different. What is the reason for the price?

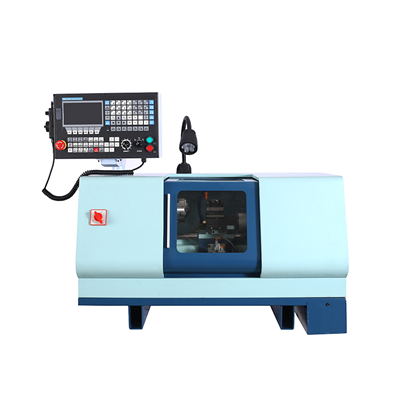

cnc engraving and milling machine system is the vertical machining center of the brain. All the actions and programs of the machining center are completed based on it. When choosing a CNC system, it is necessary to integrate various factors, such as environmental utilization, working conditions, processing technology, procurement budget, etc. In the case of low processing requirements and limited budget, we can choose the national nc system or the Taiwan system.

II. The high efficiency of the Federal

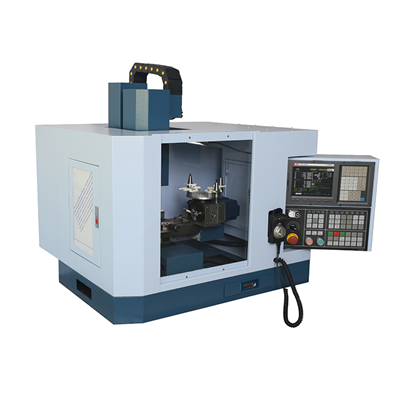

five-axis machining center lies not only in a fine operating system, but also in a very important auxiliary feature, that is, the tool magazine. The tool magazine is the container of the machining center tool. The commonly used tool magazine in the machining center has a barrel cap type tool magazine and a disc type tool magazine. The disc type tool magazine is also called the robot tool magazine or the cutter arm type tool magazine.

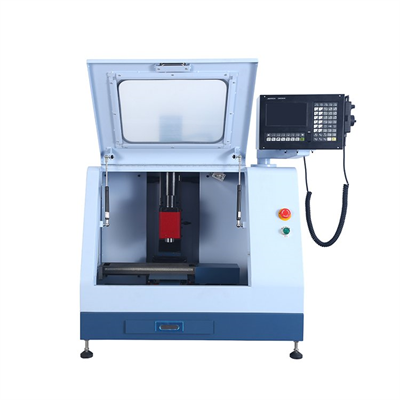

III. Spindle unit

Spindle speed is generally very high, all above 8000rpm/min. Spindle speed above 10000rpm/min is a kind of high-speed spindle. In high-speed machining, the engraving and milling machine tool will generate a lot of heat. High chip heat connection will be generated on the machine table and the surface of the workpiece, which will not only affect the machining accuracy of the workpiece, but also damage the machine tool. Therefore, the spindle will be an oil or water cooling The general transmission mode of the spindle is belt drive and direct drive, direct drive is suitable for high-speed light cutting.

four. Price gap between hard wire

hard rail machine is slower, but more rigid, anti-collision, mainly used for large cutting, mold. The speed and accuracy of the rail machine are mainly used for light cutting, products, relatively long life without hard rail machine. bt400 bed track more, bt50 bed rectangular guide more. Now many people buy vertical machining center will choose two lines and one hard wire, because this can improve speed, increase cutting force, high performance and price ratio.

Development and prospect of numerical control engraving and

Development and prospect of numerical control engraving and

Advantages of mechanical spindle of large numerical control

Advantages of mechanical spindle of large numerical control

The numerical control engraving and milling machine with str

The numerical control engraving and milling machine with str

Machining center numerical control engraving and milling mac

Machining center numerical control engraving and milling mac