Main function of wire cutting in engraving and milling machine

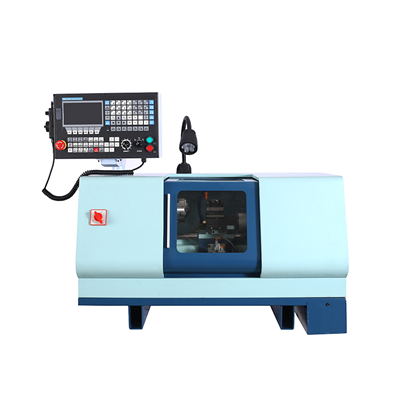

The main functions of the high-speed milling manufacturer's large-taper EDM wire cutting machine tool: The engraving and milling machine series EDM wire cutting machine tool is used for the large-taper EDM wire cutting machine tool, which can process metal molds, avoid metal parts, precision templates and all conductor objects such as difficult machining.

Large taper, large thickness, high efficiency, high precision, new structure, etc. Protection and alarm functions: automatic protection of wire winding, automatic shutdown of the machine tool, automatic reverse protection of short circuit, power failure memory protection, automatic short circuit alarm, automatic disconnection alarm, automatic shutdown alarm processing, priority processing.

Large taper tangent machine tool main structure:

small gantry engraving and milling machine taper host adopts box structure, product information is based on CAD simulation force stiffness calculation.

First, the production and processing floor plan is uneven, light

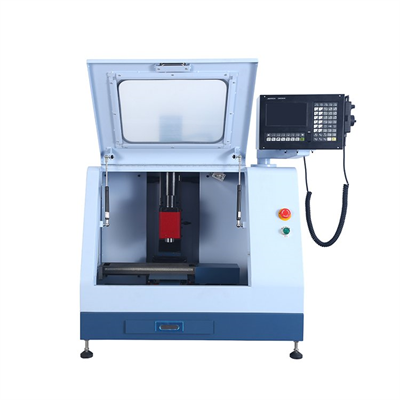

In the machining of parts of the cnc milling machine, the deep processing of the surface is a key process flow, and it is also a process flow that is often done. The quality requirements for the surface layer are higher. However, in the specific production and processing, sometimes

will get uneven and not only the floor plan, which does not meet the regulations.

The key reason for this problem is that in the case of deep processing, because the characteristics of the cutting fluid cannot meet the production and processing regulations, when the tool speed is too fast, and the vibration caused by the rapid movement of the numerical control blade is very easy to leave a uneven relative path for the production and processing surface of

. Sometimes there will be a certain difference in the knife pattern between the two adjacent engraving software, which is caused by the inconsistent orientation of the drilling tool. To prevent this problem, the production and processing method of full milling should be selected and the special type of cutting fluid should be used.

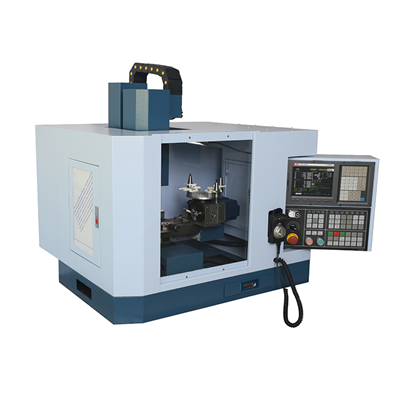

Second, the joint pattern on the side of the finishing milling machine is too significant.

In the production and processing of the product workpiece of the CNC milling machine, basically every product workpiece is specified on the side of the finishing milling, and in many cases, there will be a problem of excessive and significant joint pattern on the side of the finishing milling. This is definitely not allowed, which will seriously endanger the appearance of the product workpiece. The key reason for this problem is the poor selection of the parts and main parameters of the feed, and the different cutting methods shown by the production and processing mobile phone software will also be different, but they are all deep selection of the lower knife and the main parameters of the entry and exit knife. In addition, when applying non-special cutting fluid, due to insufficient extreme pressure wear resistance, the oil slick cracked in an instant during the production process, causing scratches on the product workpiece.

Development and prospect of numerical control engraving and

Development and prospect of numerical control engraving and

Advantages of mechanical spindle of large numerical control

Advantages of mechanical spindle of large numerical control

The numerical control engraving and milling machine with str

The numerical control engraving and milling machine with str

Machining center numerical control engraving and milling mac

Machining center numerical control engraving and milling mac