How to break the high-speed engraving and milling machine

Our country is a country with a large number of manufacturers of numerical control engraving machines in the world. However, due to the large gap between domestic cnc machine tools and foreign imported equipment in design, materials, technology, parts processing, etc., the domestic cnc machine tool capacity is very low, and a large number of cnc machine tools need to be imported from abroad every year. In the future, the development trend of the machine tool industry will develop in the direction of automation, intelligence and environmental protection.

The emergence of intelligent cnc machine tools can effectively liberate people, improve the production efficiency of enterprises, reduce unnecessary labor costs, and enable machine tools to achieve more accurate and efficient processing in the production process. Tang, manager of Dongguan Branch of Rongtian Precision Machinery in 2015, said that the emergence of intelligent cnc machine tools has created conditions for the production automation of the equipment manufacturing industry in the future. The engraving and milling machine combines precision manufacturing technology with computer and network technology, which is the main direction of the development of machine tools in the future. In the working process, intelligent machine tools can carry out comprehensive and OurHours monitoring, diagnosis and correction of various deviations in the production process, providing a solution for Z-optimal production and real-time adjustment that traditional machine tools cannot complete. According to Tang, intelligent machine tools can effectively improve the production efficiency of enterprises. Compared with traditional machine tools, the production of precision parts is more convenient and efficient, and at the same time, it can effectively reduce the scrap rate and production cost.

In addition, highly automated intelligent machine tool design can reduce labor costs. High-speed engraving and milling machines give people time and energy to deal with more problems that intelligent machine tools cannot solve. This is a very important step in the transformation of traditional manufacturing industry. Rabbit to tedious operation, will liberate more people from repetitive mechanical labor, close to automation or even realize all automation. According to relevant analysis, the development of information technology and its integration with traditional machine tools have made machine tools develop towards digitalization, integration and intelligence. The application space of digital manufacturing equipment, digital production lines and digital factories will be increasingly large. Intelligent technology is used to realize intelligent decision-making, process adaptive control, error compensation intelligent control, complex curved surface plus ⅰ motion trajectory optimization control, fault self-diagnosis and intelligent maintenance and information integration. However, although our country has been committed to the development of intelligent machine tools with independent intellectual property rights, there is still a fixed gap with the industrial production of big countries at this stage. The lack of technology is still the main reason restricting the development of intelligent machine tools in our country.

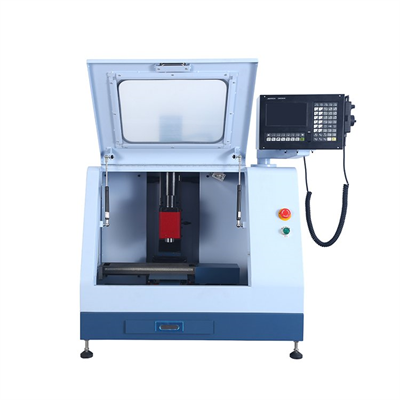

Development and prospect of numerical control engraving and

Development and prospect of numerical control engraving and

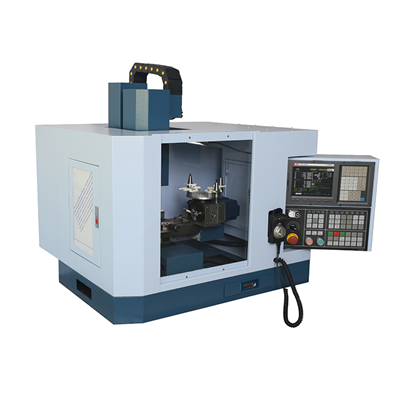

Advantages of mechanical spindle of large numerical control

Advantages of mechanical spindle of large numerical control

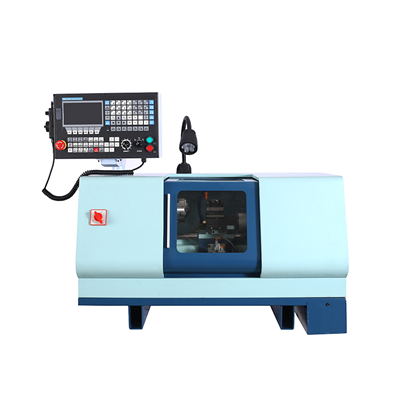

The numerical control engraving and milling machine with str

The numerical control engraving and milling machine with str

Machining center numerical control engraving and milling mac

Machining center numerical control engraving and milling mac