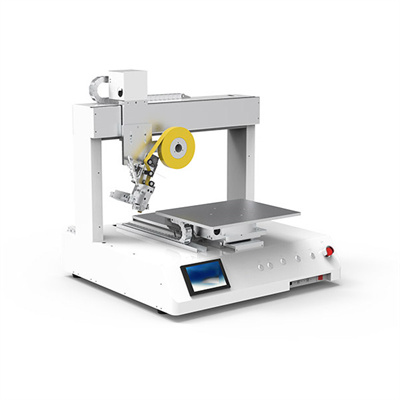

Technical Analysis of Round Bottle Labeling Machine: The Perfect Balance of Accuracy and Efficiency

Core Highlights

Round Bottle Labeling Machine As the core equipment of the automated packaging line, its technical iteration has broken through the traditional limitations. The latest fully automatic horizontal model adopts a dual control system of servo motor + encoder to achieve a label edge alignment error of 0.3mm, which can maintain high accuracy even when facing a small round bottle with a diameter of 20mm. The equipment uses the bottle splitting mechanism + labeling tape dynamic rolling and covering technology to ensure that the label is bonded without folds on the cylindrical surface. The labeling speed reaches 120pcs/min, and the 24-hour continuous operation stability has been measured. The error rate is less than 0.1%.

Industry application scenario

Pharmaceutical industry: support three-level authority management + MES system docking, in line with GMP certification requirements, 100% compliance of Xilin bottle labeling

Daily chemical field: original bottom support mechanism design, can accurately handle olive oil saddle bottles and other special-shaped containers, supporting UV curing system to solve the problem of transparent label foaming

Food and beverage: IP65 protection of the whole machine + 304 stainless steel material, after 100,000 water flushing test without failure, suitable for high temperature humid and cold environment

Technical breakthrough point

Modular design: 3 minutes quick change, single adjustment parameters 3, compatible with diameter 20-150mm full-size round bottle

Intelligent temperature control system: It can still maintain the sticky and stable label glue in a high temperature environment at 50 ° C, and prevent the phenomenon of off-label

Energy consumption optimization: Servo traction model power is only 980W, congeneric products than 35% energy saving, annual electricity savings of over

yuan

Full analysis of the core technology of the round bottle lab

Full analysis of the core technology of the round bottle lab

A must-see when buying a side labeling machine! 90% of compa

A must-see when buying a side labeling machine! 90% of compa

Technical Analysis of Round Bottle Labeling Machine: The Per

Technical Analysis of Round Bottle Labeling Machine: The Per

Innovative Technology and Customer Evidence of Round Bottle

Innovative Technology and Customer Evidence of Round Bottle