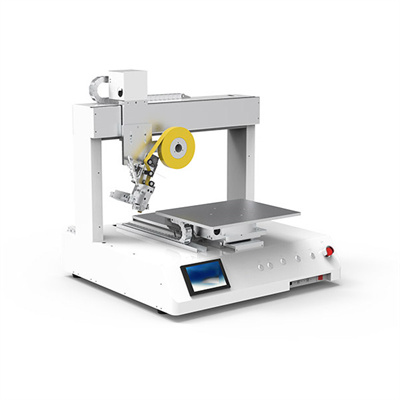

Full analysis of the core technology of the round bottle labeling machine: how to achieve efficient and accurate labeling?

In the daily chemical, food, medicine and other industries, the labeling efficiency of round bottle products directly affects the overall production capacity of the production line. A high-quality round bottle labeling machine needs to meet the three core requirements of high-speed operation, high-precision positioning, and multi-bottle type adaptation at the same time. This article is disassembled from the bottom of the technology to take you to understand the selection logic of professional equipment.

First, the technology of round bottle labeling machine, moat

Adaptive positioning system

adopts servo motor + encoder double closed-loop control. Combined with the automatic detection algorithm of bottle diameter, the label conveying speed and angle can be adjusted in real time to ensure that the label and bottle curvature fit perfectly, and the error is controlled within 0.5mm.

Dynamic labeling technology

Through the combination of flexible labeling roller + negative pressure adsorption device, even in the face of special-shaped bottles (such as olive oil bottles, cylindrical gradual change bottles), labels can be pasted without bubbles and folds, and the yield is increased to 99.8%.

Multi-station collaborative design

Mainstream equipment has realized the automation of the whole process of bottle entry, labeling and bottle exit. With the visual inspection system, missed stickers and misplaced products can be automatically removed. The comprehensive efficiency reaches 300-600 bottles/minute (depending on the complexity of the bottle type).

2. Industry pain points targeted solutions

Problem 1: Small batch multi-variety production switching time

Solution: Modular design + PLC one-click type change, complete the bottle type parameter call within 10 minutes, no mechanical adjustment.

Problem 2: Cold glue/hot melt adhesive residual pollution

Solution: Using contactless ultrasonic glue spraying technology, the diameter of the glue point can be controlled within 0.3mm, reducing the amount of glue used by 30% and no risk of glue dragging.

Problem 3: Wet bottle body labeling warping

Solution: Configure infrared pre-drying module to quickly dehumidify the bottle body for 2 seconds before labeling to ensure label adhesion.

Full analysis of the core technology of the round bottle lab

Full analysis of the core technology of the round bottle lab

A must-see when buying a side labeling machine! 90% of compa

A must-see when buying a side labeling machine! 90% of compa

Technical Analysis of Round Bottle Labeling Machine: The Per

Technical Analysis of Round Bottle Labeling Machine: The Per

Innovative Technology and Customer Evidence of Round Bottle

Innovative Technology and Customer Evidence of Round Bottle