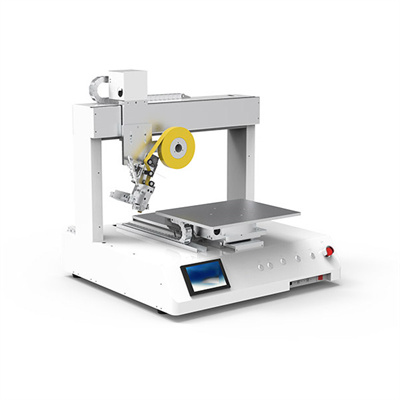

A must-see when buying a side labeling machine! 90% of companies have stepped on these 5 pits

Faced with the labeling machine traps of false labeling of parameters and after-sales prevarication on the market, we sorted out the 5 core indicators that are most easily overlooked when selecting enterprises, and included the actual combat cases of leading enterprises.

Selection pit avoidance list:

Labeling accuracy ≠ Final accuracy

It is necessary to confirm whether the equipment contains a visual compensation system, otherwise the mechanical error + product tolerance may make the actual accuracy exceed 2mm.

Compatibility trap

Be vigilant against the "maximum compatible diameter" parameter, and confirm the minimum compatible size to avoid empty labels when labeling vials.

Consumable compatibility

requires suppliers to provide a list of label materials that have been actually tested. Special materials (such as laser film) need to be customized.

wiring adaptability

Confirm whether it supports mainstream PLC protocols (such as Siemens, Mitsubishi), otherwise the cost of online transformation may exceed the equipment price by 30%.

Maintenance cost Black hole

Preference is given to models designed without oil lubrication. Traditional oil pump maintenance can save 5,000 + yuan in consumables every year.

Full analysis of the core technology of the round bottle lab

Full analysis of the core technology of the round bottle lab

A must-see when buying a side labeling machine! 90% of compa

A must-see when buying a side labeling machine! 90% of compa

Technical Analysis of Round Bottle Labeling Machine: The Per

Technical Analysis of Round Bottle Labeling Machine: The Per

Innovative Technology and Customer Evidence of Round Bottle

Innovative Technology and Customer Evidence of Round Bottle