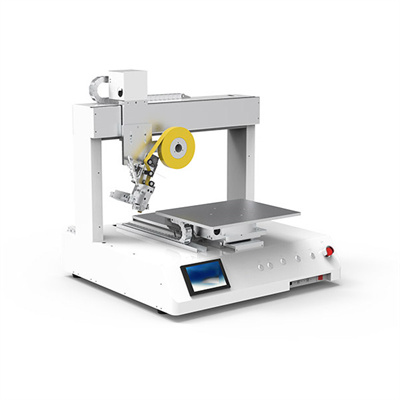

Innovative Technology and Customer Evidence of Round Bottle Labeling Machine

The intelligent vision system

integrates industrial cameras and AI algorithms, and the equipment can automatically identify the diameter of the bottle (20-120mm) and the deviation of the label position. In the case of a cosmetic company, when the system detects that the label skew exceeds 0.5, it immediately starts the fine-tuning mechanism for dynamic compensation, so that the pass rate increases to 99.8%.

Flexible production configuration

adopts snap-on guide rails and magnetic label trays, and supports switching between glass bottles, PET bottles, and composite film bottles within 5 minutes. A pharmaceutical company reduces equipment downtime by 68% through this function, saving over 200,000 yuan in annual replacement costs.

Dynamic Tension Control

For the problem of label drift in high-speed production lines (up to 800 bottles/minute), the original algorithm adjusts the standard speed in real time, and cooperates with the vacuum adsorption belt to ensure synchronous rotation. The measured data shows that under the running state of 600 bottles/minute, the labeling integrity rate remains above 99.7%.

Full analysis of the core technology of the round bottle lab

Full analysis of the core technology of the round bottle lab

A must-see when buying a side labeling machine! 90% of compa

A must-see when buying a side labeling machine! 90% of compa

Technical Analysis of Round Bottle Labeling Machine: The Per

Technical Analysis of Round Bottle Labeling Machine: The Per

Innovative Technology and Customer Evidence of Round Bottle

Innovative Technology and Customer Evidence of Round Bottle