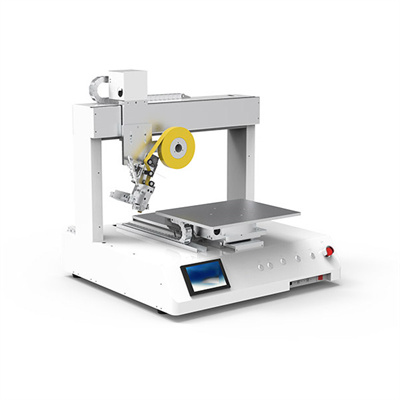

Upper and lower plane labeling machines: precision labeling solutions in industrial automation

1. Technical core: Realization of millimeter-level accuracy

The upper and lower plane labeling machine is linked with the servo motor through high-precision sensors, and uses image recognition or photoelectric detection technology to calibrate the label position in real time, and the error is controlled within 0.5mm. Its adaptive speed adjustment algorithm can match the speed of the conveyor belt of the production line. Even in the face of special-shaped planes (such as bottle caps, cartons) or curved transition products, it can achieve "zero delay" labeling to avoid label wrinkles or deviations. High-end models support dual or even four-header simultaneous work, which can complete complex requirements such as front and back labeling and multi-label combination labeling at the same time. The efficiency of a single machine is increased by more than 200%.

2. Application Scenario: Cross-industry Efficiency Revolution

Food Packaging: Moon Cake Gift Box Double-sided Labeling In the case, the equipment achieves 99.8% label flatness through vacuum labeling + rotating labeling head, and the waste labeling rate is only 0.1%. Single-line labor costs are reduced by 70%, and capacity utilization is increased from 85% to 95%.

Pharmaceutical Manufacturing: Integrated three-level association system, in line with the "Drug Traceability Code Identification Specification". A vaccine enterprise realizes zero missed reading of the traceability code after application. The annual provincial quality inspection labor cost is 380,000 yuan, and zero defects have passed the FDA audit.

Consumer Electronics: 3D Vision Guidance + Six-axis Robot System, in the mobile phone charger production line to achieve zero poor labeling, positioning accuracy is 0.1mm, and the annual rework loss is reduced by 2.10 million yuan.

Full analysis of the core technology of the round bottle lab

Full analysis of the core technology of the round bottle lab

A must-see when buying a side labeling machine! 90% of compa

A must-see when buying a side labeling machine! 90% of compa

Technical Analysis of Round Bottle Labeling Machine: The Per

Technical Analysis of Round Bottle Labeling Machine: The Per

Innovative Technology and Customer Evidence of Round Bottle

Innovative Technology and Customer Evidence of Round Bottle